Products Detailed:

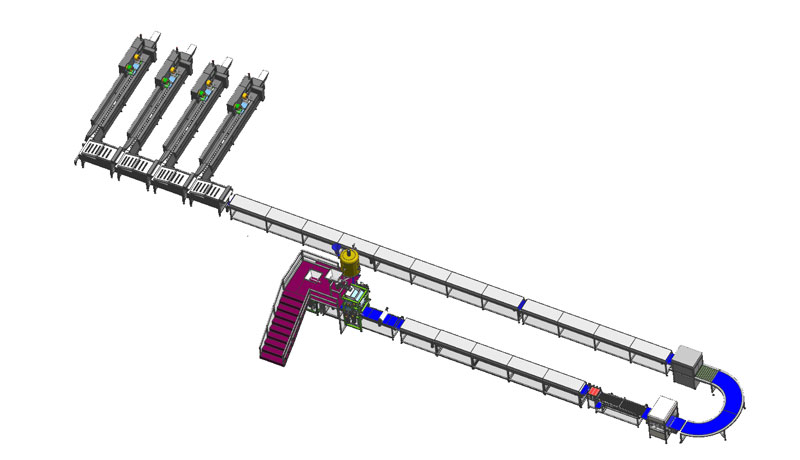

Automatic Slab bar production line for snicker, candy bar, energy bar, slab bar.

Machine Main Structure:

1.the Forming Rollers unit and pressed rollers.

2.the cooling and conveying.

3.longitudinal cutting and spreading

4.transversal cutting(ultrasonic and stainless steel knife for the choice)

5.Chocolate enrobing and cooling

6.distribution and packing

Application:

Snicker, nougat, cereal bar, slab bar ,energy bar,protein bar,muesli bar, square shape candy automatic production.

Advantage:

1.automatic production from pressing, conveying, cooling , cutting.

2.PLC and servo motor control, rapid and precise reaction

3.Product thickness can be easily adjusted through slip wheel.

4.product cutting length can be set on touch screen.

5.Longitudinal cutting spread each bar for well forming and uniform shape.

6.transversal cutting spread each bar in back and forth.

Technical parameter for longitudinal and transversal cutter:

| Model | CP-500 | CP-800 |

| Product Description | For bar mass 330mm before spreading | For bar mass 550mm before spreading |

| Machine materials | SS 304 | SS 304 |

| Knives coating | Teflon coating by Dupont | Teflon coating by Dupont |

| Cutting Length | 20-200mm | 20-200mm |

| Product Width | Customized according to client's requirement | Customized according to client's requirement |

| Cutting speed | General cutter:100times/min Ultrasonic cutter:80times/min | |

| Servo Motor Brand | Panasonic | Panasonic |

| Power | Two servo motors: one is 1.5kw,another is 4.5kw | Two servo motors: one is 1.5kw,another is 4.5kw |

| Longitudinal cutting machine(slitting machine) | 3200*750*1600mm | 3400*1200*1600mm |

| Transversal cutting machine | 2000*1200*2000mm | 2000*1200*1600mm |